That unsettling rattle echoing through your vents is more than a seasonal annoyance—it’s your furnace asking for attention. Those metallic shakes, thumps, and hums don’t just interrupt quiet evenings; they can hint at loose parts, tired components, or airflow issues waiting to escalate. Understanding what’s behind the sound can prevent costly repairs and restore peace to your home before the noise grows into a breakdown.

Loose Panels or Fasteners Triggering Cabinet Vibration

A furnace cabinet houses several panels that protect its internal components. Over time, heat expansion and cooling cycles cause screws and fasteners to loosen. Once that happens, the panels begin vibrating against the frame, creating a harsh rattling sound that’s often mistaken for something major. Tightening these panels is a simple fix, but leaving them loose can wear down the sheet metal and increase resonance.

Ignoring this kind of vibration also allows friction to weaken mounting points. The longer the system runs with unsecured panels, the louder and more erratic the sound becomes. Periodic inspections during routine furnace cleaning help ensure all fasteners stay secure, keeping your unit stable and whisper-quiet through every heating cycle.

Worn Blower Bearings Inducing Unstable Oscillation

The blower assembly is responsible for circulating warm air, and its bearings keep the fan wheel rotating smoothly. Over years of use, those bearings dry out or wear down, causing the blower shaft to wobble. That imbalance produces a rattling or scraping sound that grows louder as the system runs. Early attention prevents the fan motor from suffering more serious damage.

If ignored, worn bearings can overheat the motor and strain electrical components. You might notice the furnace struggling to reach set temperatures because the blower can’t maintain steady airflow. A professional tune-up can replace the bearings and apply fresh lubrication, restoring balance to the fan’s motion and extending the lifespan of the furnace.

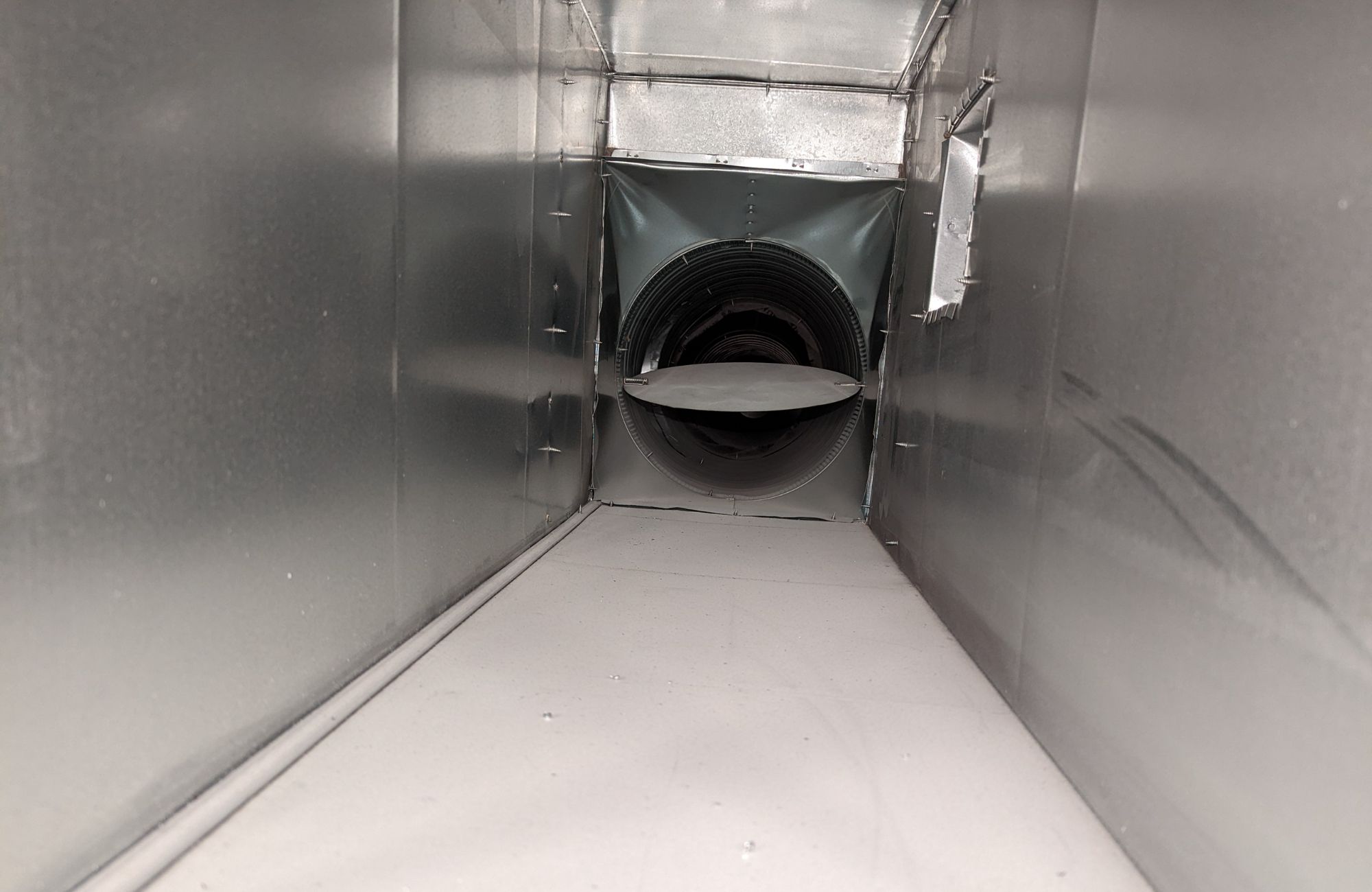

Misaligned Duct Joints Creating Reverberant Noise

The metal ductwork connected to your furnace expands and contracts with temperature shifts. Over time, these sections can drift out of alignment, leaving small gaps or loose joints. Air moving through these misaligned ducts vibrates the metal, generating a deep reverberant hum that travels through walls and vents.

This problem not only creates noise but also reduces system efficiency. Air leaks mean heated air escapes before reaching living spaces, forcing the furnace to work harder. Technicians can reseal duct joints using high-quality mastic or foil tape, preventing rattles while improving overall airflow. Correcting alignment also ensures the heat reaches every room evenly.

Cracked Heat Exchanger Producing Pre-ignition Rumble

A furnace’s heat exchanger separates combustion gases from indoor air. If it cracks or warps, the combustion process changes—fuel ignites unevenly, producing a low rumble or metallic rattle before each cycle. This noise may signal gas buildup, which poses a serious safety hazard.

A cracked exchanger also reduces heating efficiency and can allow harmful exhaust gases into your home. Once detected, the part should be replaced immediately. Professionals inspect exchangers for cracks using specialized lighting tools, ensuring proper combustion safety. Addressing this issue early not only eliminates the noise but keeps your household safe and comfortable.

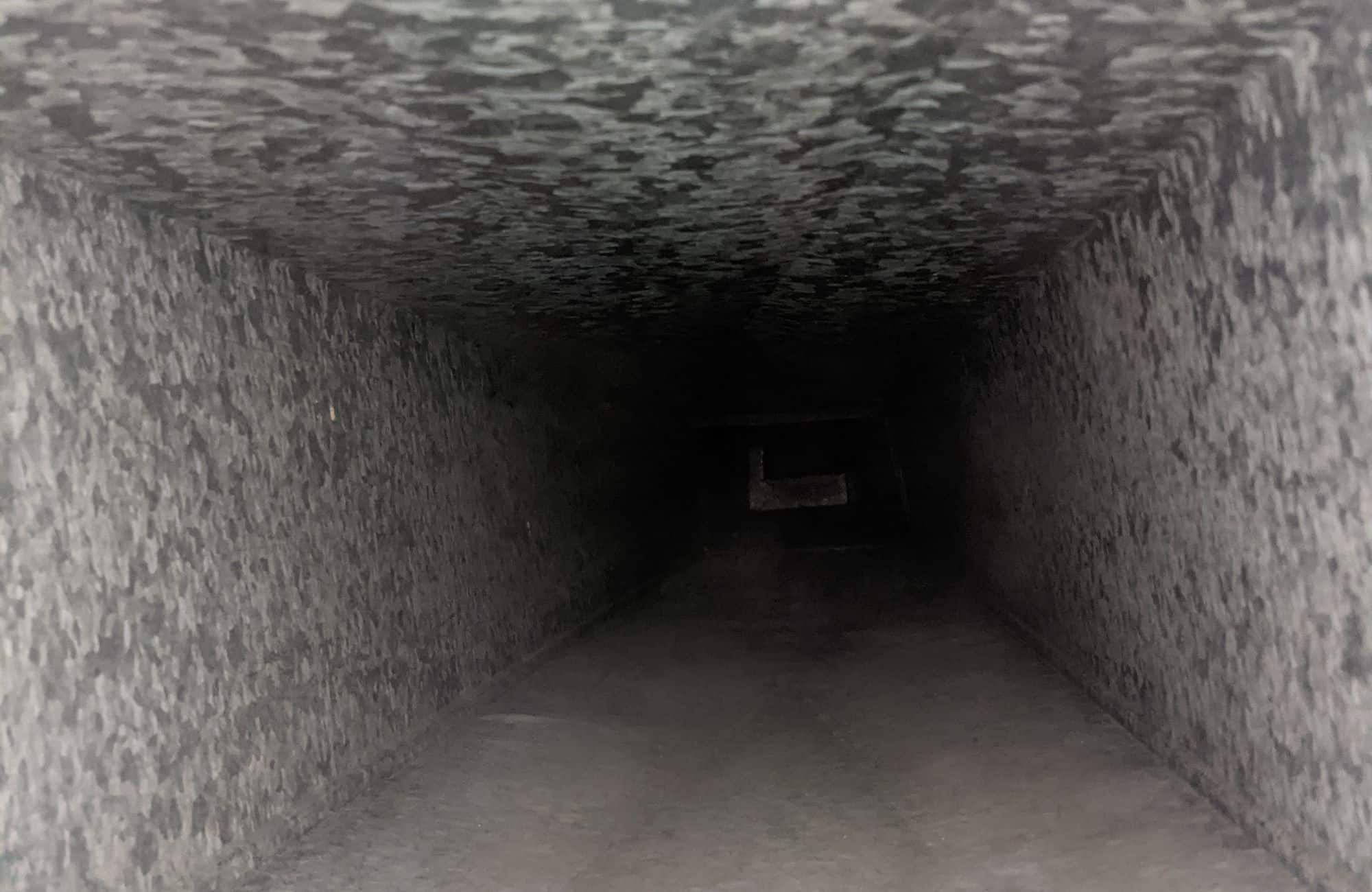

Dirty Filters Constricting Airflow and Amplifying Vibration

Clogged filters block airflow, forcing the furnace to pull air through narrow passages. The extra strain causes the blower wheel and ducts to vibrate more aggressively, creating rattling or thumping noises during operation. Dirty filters also make it harder for the system to regulate temperature consistently.

Changing filters regularly allows air to flow freely and reduces mechanical stress on the blower. During professional furnace cleaning, technicians inspect and replace filters that show buildup or discoloration. Clean filters not only quiet your system but also improve indoor air quality and lower utility bills.

Imbalanced Blower Wheel Striking Housing Edges

If your furnace suddenly begins making rhythmic tapping sounds, the blower wheel might be out of balance. Dust accumulation or bent blades can throw off the wheel’s rotation, causing it to strike the housing as it spins. This produces a rapid metallic rattle that increases with fan speed.

An unbalanced wheel puts pressure on the motor shaft and bearings, leading to premature wear. Technicians can remove the assembly, clean it thoroughly, and straighten any bent fins to restore smooth rotation. Keeping the blower balanced ensures quieter performance and a longer-lasting motor.

Loose Burner or Gas Valve Components Rattling Under Flame Dynamics

Inside the burner assembly, gas valves and burner tubes regulate fuel delivery. Over time, the small screws or mounting brackets that secure them can loosen from constant temperature changes. When the gas ignites, the vibration causes these metal parts to chatter or click.

This rattle often grows louder during startup or shutdown as pressure fluctuates in the system. While it may sound minor, loose gas connections can lead to uneven ignition and wasted fuel. A qualified technician should inspect these components, tightening fittings and ensuring safe combustion alignment. Regular maintenance prevents recurring vibrations and keeps heating consistent.

Vibrating Sheet-metal Flue Sections Resonating with Airflow

The flue pipe channels exhaust gases safely out of the furnace. When its sheet-metal sections become misaligned or unsecured, they vibrate with the pressure of moving air. This vibration creates a hollow drumming sound that echoes through the vent system.

These noises tend to appear during high fan speeds or windy conditions. Adjusting brackets, adding support straps, and tightening fasteners usually stop the resonance. A well-secured flue pipe ensures exhaust gases flow efficiently and keeps unwanted noise from disrupting your home’s comfort.

Aging Motor Mounts Failing to Dampen Operational Jolts

Motor mounts act as cushions between the blower motor and the furnace frame. As they age, the rubber or polymer inside them hardens or cracks, losing their ability to absorb vibration. The result is a harsh rattling sound as the motor vibrates directly against the metal housing.

Replacing old mounts restores the buffer that keeps the furnace steady during operation. This small fix not only reduces noise but also protects internal wiring from loosening due to constant vibration. During seasonal maintenance or furnace cleaning, technicians often check motor mounts to ensure they remain flexible and properly aligned.

Restore Peace and Comfort with Reliable Furnace Cleaning and Repair by Duct Dudes

A furnace that rattles is trying to tell you something—and ignoring it can shorten your system’s lifespan or create unsafe conditions. Loose hardware, clogged filters, and worn components don’t just make noise; they reduce efficiency and strain every moving part. The professionals at Duct Dudes specialize in diagnosing and eliminating these sources of vibration through thorough inspection, part replacement, and expert furnace cleaning.

Our team understands how vital a quiet, efficient system is for comfort and safety during long heating seasons. From tightening panels to rebalancing blower assemblies, every service focuses on restoring stability and reliability. Stop living with the hums and rattles that keep your home from feeling peaceful. Contact us today to schedule an inspection or furnace cleaning with Duct Dudes—and experience the calm of a furnace that runs as quietly as it should.